Electric Mobility is the Future, But What Exactly do I Need to do?

The EV industry is set to boom in a big way, you have likely heard this ‘n’ number of times by now. As a supplier you may have been thinking, how exactly am I going to benefit from this, given the vast application area and complex value chain among many other variables? This paper will focus on clarifying the EV space for panel builders, OEMs, machine builders and provide the driving factors, areas to focus on, and how to make the most out of this new trend.

Let us start with understanding the scope first.

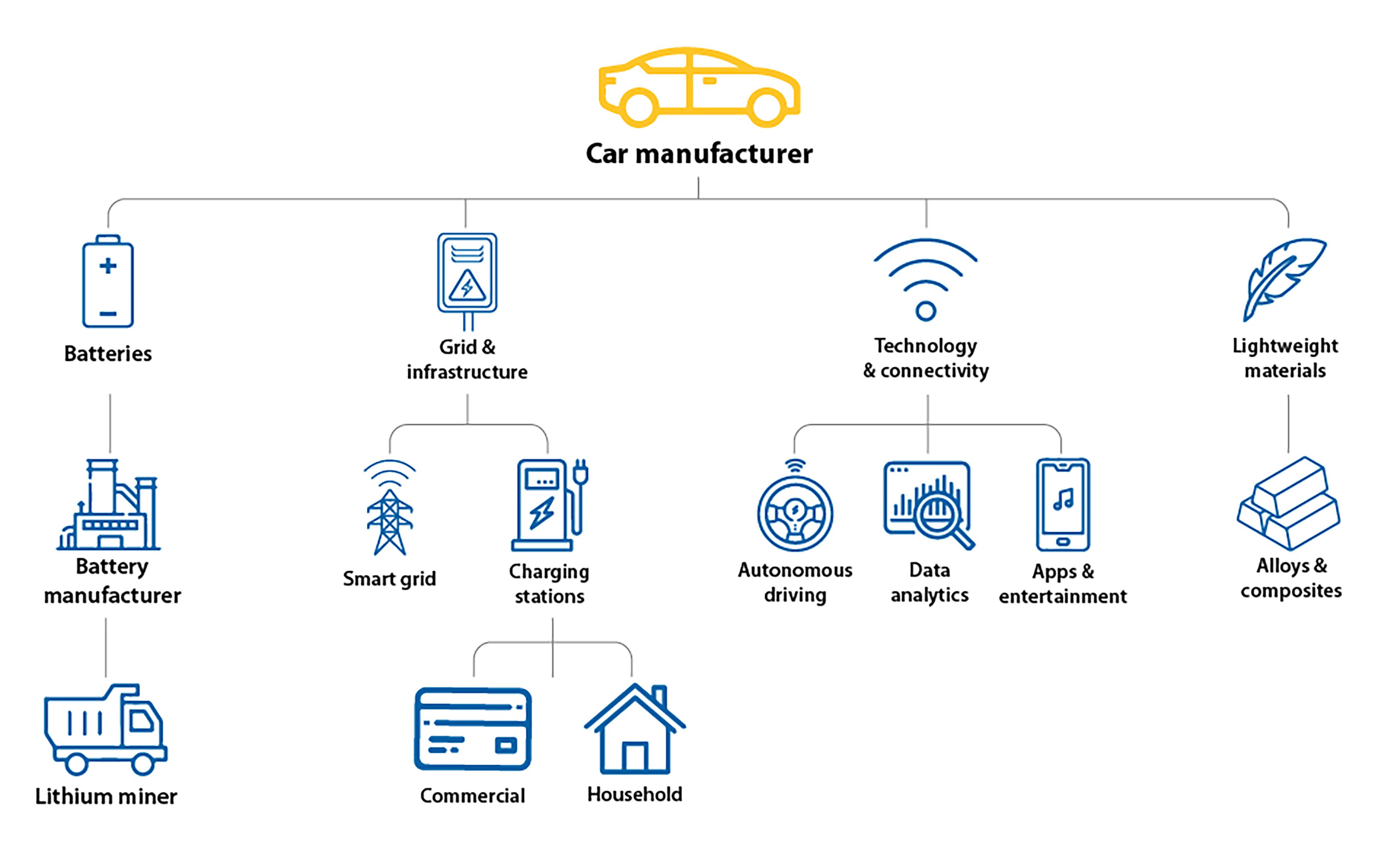

The electric mobility ecosystem consists broadly of three components:

- Car manufacturer:

These are large established consumer facing firms making EVs, yes Tesla rules here. (Although there are others entering the market.) This will include their Tier 1, 2 and 3 suppliers as well. - Battery manufacturer:

This is probably the most important vertical in this space. It will not just include battery manufacturers, but also involves key raw material suppliers such as Lithium miners. - Grid and Infrastructure enablers:

This is not an integrated part of this ecosystem, but actually, without this our Electric Vehicle will just be a piece in a museum. Apart from power generation and transmission companies, this vertical includes charging station providers — a super-important component in the whole EV space as well as for OEMs. This is the segment where the real opportunity lies.

Battery Advancement and EV Adoption

One of the biggest improvements in electric vehicles (EVs) has come from better batteries. In the past, people were nervous about running out of power—EVs didn’t go very far on a single charge. But now, thanks to stronger batteries, many EVs can drive over 200 miles without needing to recharge.

Because of this, more people feel comfortable switching to electric cars. The fear of getting stuck without a charging station is going away, as battery technology keeps improving. Simply put, as batteries get better, more people are choosing EVs.

So, let’s take a deep dive into EV charging stations.

Charging Stations

Charging stations can be summarized in the following categories:

- Level 1:

EV manufacturers provide a charging accessory that can be used to charge the EV through standard household power outlets. This is the slowest method of charging an EV. - Level 2:

This is an AC charging station placed mostly in commercial establishments with higher output voltages and current. They utilize an On-board charger of the EV to convert this AC input to DC to charge the battery, same as the Level 1 charging method. It operates at powers up to roughly 20kW and requires a few hours to charge the battery. - Level 3 DC Fast Charger (DCFC):

These are the super chargers, which directly feed DC supply to the battery bypassing the on-board converter. It operates at power from 25 to 350kW and charges the vehicle in around 30 minutes.

Wireless Charging & Battery Swapping:

These are also some other techniques to power up your EV, but they are still emerging and may not be viable, considering challenges such as energy wastage in wireless charging or requirement of battery standardization across the industry for making battery swapping possible.

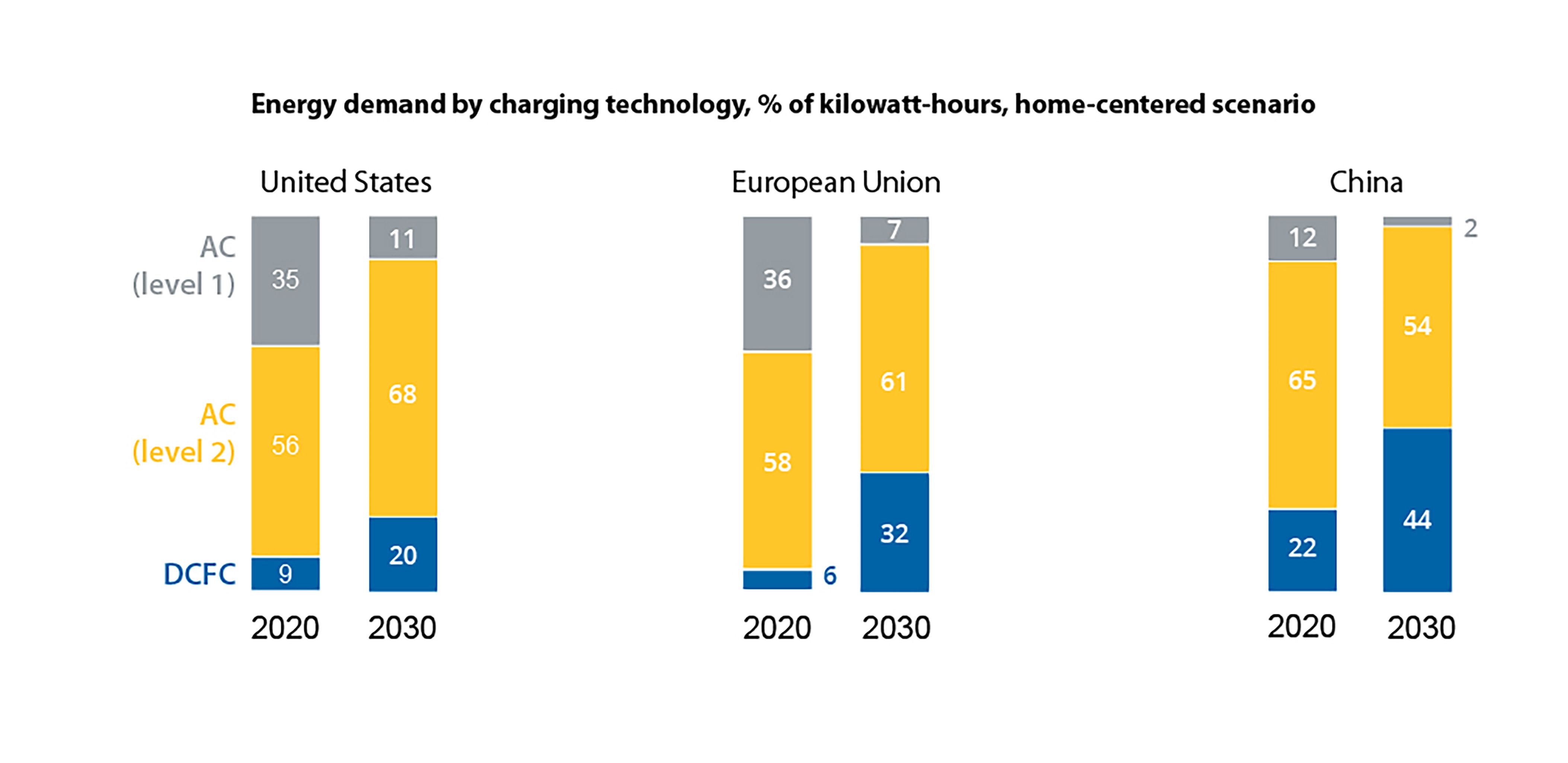

The question is where the largest market opportunity is. Per McKinsey analysis, significant share will be the Level 2 AC charging stations. The reason is quite obvious, most of the time, a vehicle will be off road, parked, whether at the workplace or home.

Another important factor which contributes to rapid adoption of Level 2 charging stations is the low upfront cost, which is often less than $5,000. Whereas the DCFC costs range from anywhere between $25,000 to $200,000, depending upon the power capacity.

Now comes the interesting part — volume and number of chargers. It is estimated that the US alone will have 13 million chargers by year 2030. Referring to the above graph, Level 2 charging stations will keep on increasing their share across the US and EU.

Is this really going to happen on such a large scale? It looks very possible. Electric is the future, thanks to the push from climate change. Governments are heavily subsidizing and incentivizing this space. For example, a recent announcement by US President Joe Biden, proposes spending of $174 billion for EV push, out of which $15 billion would be allocated for setting up 500,000 charging stations.

The above should have provided you with a basic understanding of the commercial considerations in this space. Now, let’s look at the technical aspects of Level 2 charging stations.

Level 2 AC Charging Stations

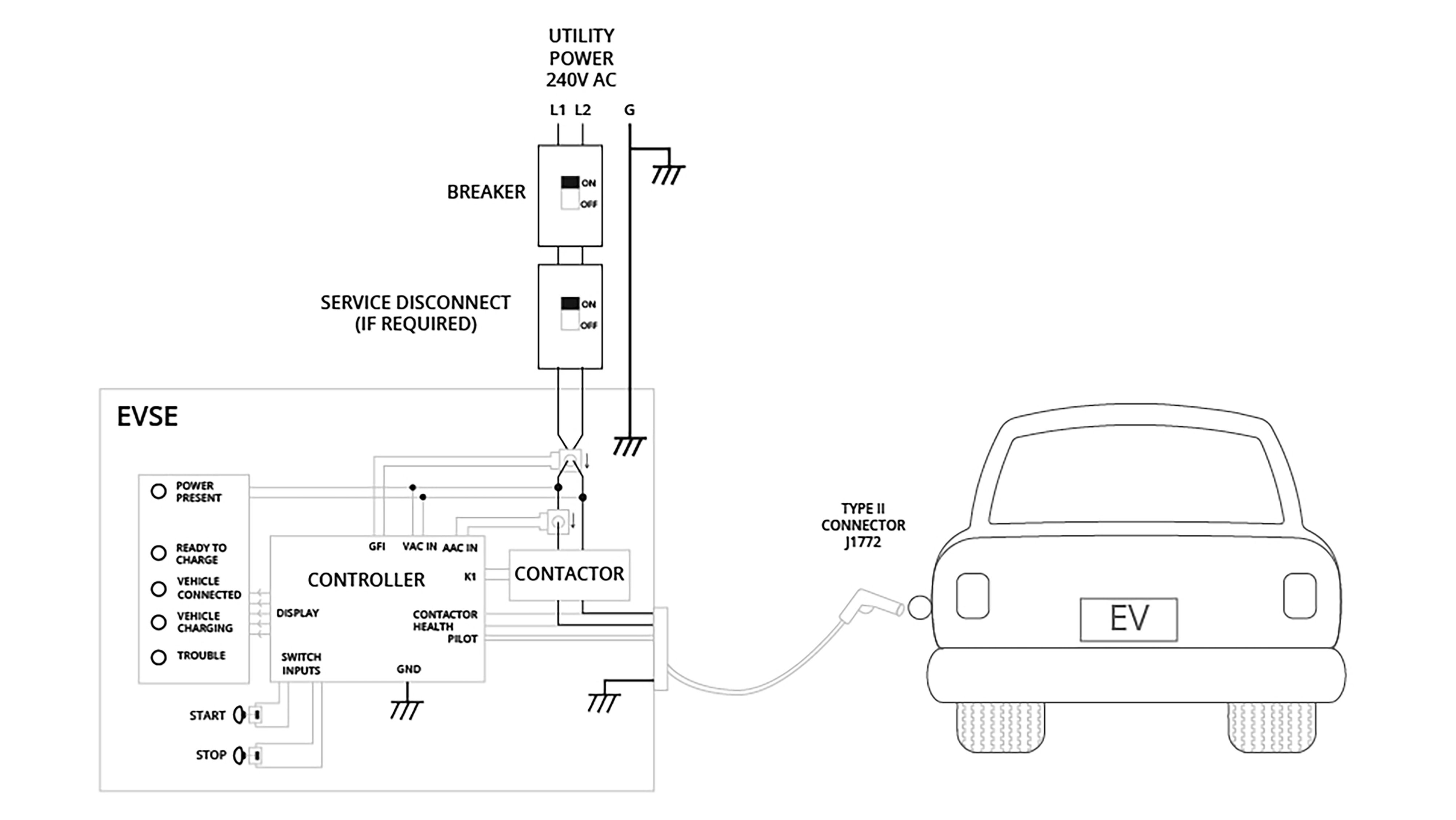

Level 2 charging stations operate with an AC input voltage of 240V (typical in residential applications) or 208V (typical in commercial applications). This charging station can pump up to 80A or 19.2kW. However, most Level 2 charging stations operate at much lower power, i.e., up to 30A or 7.2kW of power.

Below is an example of how a simple level 2 charging station looks internally.

Due to the requirements of various standards, such as UL 2594, IEC/EN 61851-22, charging stations not only include control devices but also protection components (apart from J1772 connector).

Charging Station Components

- Miniature Circuit Breakers:

Since Electric Vehicle charging stations need to be supplied by a dedicated branch circuit, protective devices such as Miniature Circuit Breakers are essential in case of adverse effects of overload and short-circuit. - Residual Current Circuit Breaker:

A charging station installed outside can be exposed to snow, dust, rain, and various temperature and humidity levels. Since it is handled by users every now and then, standards such as IEC 60364-7-722 requires a 30mA residual current circuit breaker for protection against fibrillation and electrocution which can be caused due to the earth’s leakage current. - Disconnect Switch:

Per Canadian standard 86-304, if the charging station is being operated at 60A or above or more than 150 Volts-to-ground, a separate disconnecting means is required per installation. Additionally, it should be capable of being locked in the Off position. - Surge Protection Devices:

To protect sensitive components against lightning and over-voltages, charging stations use Type 2 surge protectors as well. - Contactors:

Contactors with General purpose current rating up to 115A are mainly used for switching the power to the EV On or Off. - Energy Meters:

If the charging station is to be used for commercial purpose, then there has to be a measurement of energy consumed, based on which customers would be charged. A digital energy meter with a maximum of 80A capacity is used here for this purpose. - If a charging station is a networked one, then it would need high-tech devices such as gateways, controllers, etc. to power them all. It would also include a DC power supply requiring single or three phase input voltage. Terminal Blocks, Wire Duct, DIN Rail, etc. would also be there for ease of wiring.

Key Roles: Engineering and Computer Professionals Powering the EV Revolution

Let’s take a look at the people actually building the future of electric vehicles (EVs). It’s not just tech geeks or Elon Musk lookalikes—it’s a whole team of skilled professionals working together to make EVs smarter, safer, and more powerful.

1. Software Developers These experts create the "brains" of the EV—things like battery control systems, touchscreens, and self-driving features. With cars becoming more connected and updated through the internet, software developers are in high demand.

2. Electrical Engineers They design the EV’s main parts, like the motor and systems that send energy from the battery to the wheels. They also work on improving battery life, faster charging, and expanding charging station networks.

3. Electronics Engineers Gone are the days of simple dashboards. These engineers build the entertainment systems, safety tech (like auto-pilot), and all the tiny electronics that keep your car’s features running smoothly.

4. Chemical Engineers While we debate battery life online, chemical engineers are actually inventing better batteries. They create materials that make batteries charge faster, last longer, and are easier to recycle.

Key Occupations Shaping Electric Vehicle Design and Development

Now that we’ve mapped out the main players in the electric mobility ecosystem, let’s zoom in on the specific experts and roles that make EVs and their infrastructure possible. While you might picture “EV innovation” as something exclusive to a lab at Tesla (with a latte-fueled engineer at the helm), the truth involves a diverse cast behind the curtain.

Here’s a quick overview of the talent powering the evolution of electric vehicles:

Mechanical, Electrical, and Electronics Engineers:

Think of these folks as the architects and problem-solvers of the EV world. Mechanical engineers take charge of physical parts—everything from motors to brakes. Electrical engineers focus on the all-important flow of electrons: developing motors, power electronics, and integrating battery technology. Meanwhile, electronics engineers are busy weaving advanced systems into the car, tackling everything from infotainment dashboards and safety features (like automatic emergency braking) to battery monitoring and sensor integration.

Software Developers and IT Specialists:

Modern EVs are essentially “computers on wheels,” so it’s no surprise that software experts are vital. They create the code and systems that manage everything from battery health to self-driving features—yes, the stuff that’ll update itself over WiFi when you’re asleep. With tech like autonomous driving and over-the-air updates on the rise, this role’s importance is only accelerating.

Chemical Engineers:

Here we have the unsung heroes busy in the background, refining battery production, advancing materials science, and designing ways to recycle old EV batteries. Their work is crucial for creating batteries that charge faster, last longer, and are more environmentally friendly—a game-changer for both car owners and the planet.

These roles are not just about keeping up—they’re about staying ahead in an industry that’s transforming by the minute. Whether you’re a panel builder, OEM, or machine builder, understanding these areas is essential for making yourself indispensable in the fast-evolving EV value chain.

We hope the information provided in this paper has helped you better understand the Electric Vehicle market. c3controls offers most of the products required to build a charging station. We are just a phone call away, ready to assist you in your journey in EV.

----------

Check out the other articles in this Series on Electric Vehicles - New Trends in Technology.

--------------------

Disclaimer:

The content provided in this document is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information in this document was posted with reasonable care and attention. However, it is possible that some information in this document is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this document.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009